KAMA ProCut 76

High-quality and efficient further processing in conventional and digital printing.

Punching, creasing, perforating... most printed products only really take shape during further processing.

Punching

Grooves

Perforate

Blind embossing

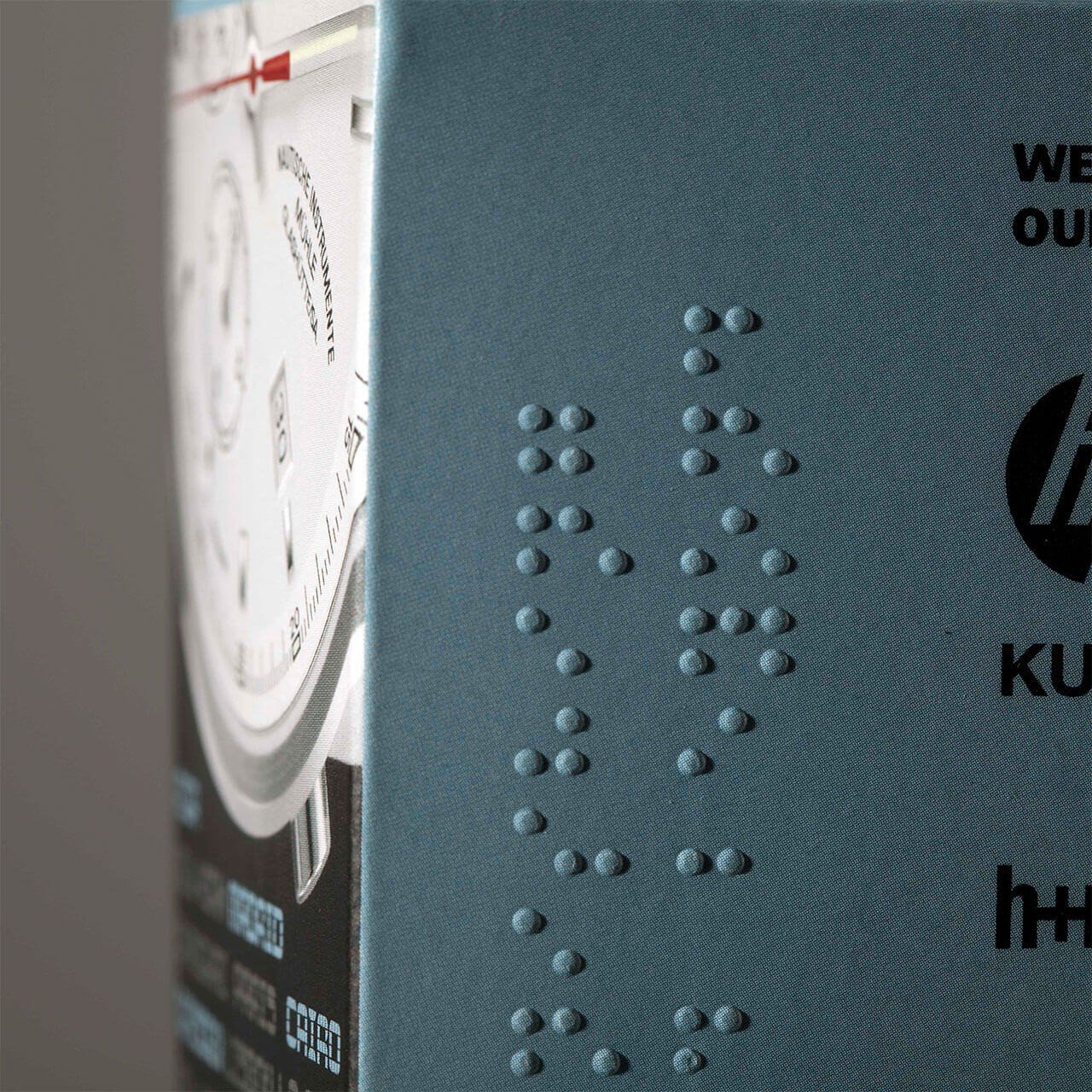

Embossing Braille

Punching

ProCut 76 die cutting and stamping machine

The ProCut 76 die cutting and stamping machine is the professional solution for finishing in the sheet size B2 (760 x 600 mm).

Short set-up times, time-saving features and high-quality outputs make the flat-bed die butter a reliable and cost-effective solution for finishing in the commercial printing sector and beyond. With the KAMA AutoRegister, you can also cut and crease digitally printed sheets with high registration accuracy, allowing you to address the new market for short runs in packaging.

The versatile ProCut 76 is suitable for many different applications and is a perfect, state-of-the-art successor for worn-out cylinders and platen presses that are past their use-by date. And in the process, you can simply carry on using any tools you already have. The ProCut 76 is network capable and can be retrofitted for use in hot foil stamping applications

Highlights of the ProCut 76

Versatile

Flexible & efficient for small to medium print runs.

Gentle sheet travel in one plane, clean creasing lines, precise embossing and punching without stopping points: The ProCut 76 is the flexible solution for further processing paper, cardboard and plastic in B2 sheet format. It can be retrofitted for hot punching of plastic or for finishing with hot foil.

Fast conversion

Relevant for short runs and digital printing.

Fast order changes are absolutely essential for smaller runs and digitally printed jobs. On the ProCut 76 it takes just around 5 minutes to convert the setup, which means that the next order can start up quickly – thereby making post-press finishing profitable. The 4+1 system with prepared 1 mm plates also ensures that uptime is maximised. With the type of repeat orders involving intensive creasing, which are common in packaging jobs, this can shorten set-up times by up to 90%.

Highest registration accuracy

… including for digitally printed and cut sheets.

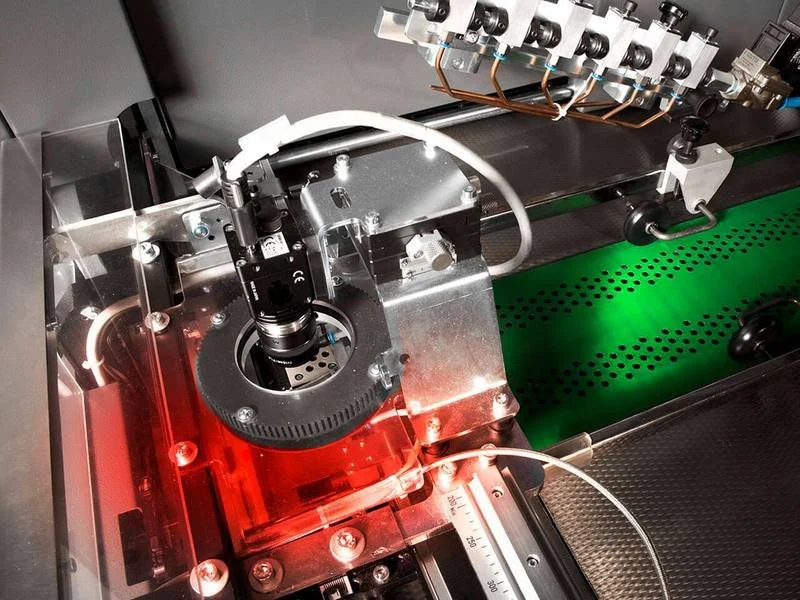

With the linear KAMA gripper, ProCut die cutting and stamping machines achieve the highest registration accuracy on the market. The AutoRegister guarantees the highest precision for digitally printed sheets and for sheets that are cut after printing. At aligns every sheet based on the print image, and cutting and creasing lines are accurately positioned to within an accuracy of a tenth of a millimetre.

Continue using tools

Smooth transition to the new solution.

You can continue to use existing tools with the universal closing frame on the ProCut 76 without any problem. This also applies to small cutting dies.

AutoRegister AR3

NEW: The AutoRegister AR 3 also corrects in the diagonal direction with "skew adjust" - for the highest registration accuracy for cut and twisted sheets, multiple finishing and the most demanding packaging.

Compact machine

Lots of functionality in a small space.

With a footprint of around 12 m2 including the platform, the ProCut 76 requires very little space. Thanks to the sheet transport at a right angle at the feeder, the compact machine can also be placed in a corner.

-

Equipment examples for the ProCut 76

The KAMA AutoRegister aligns each sheet to the print image. Ideal for further processing in digital printing.

4+1 removable plate system for quick job changes

Universal locking frame for use with existing tools

Magnetic plate for punching and cutting the finest contours

Can be retrofitted with embossing systems for hot foil and hologram

Hot-Cut system for hot punching and creasing of plastic

-

Multi-level cold embossing.

Small details, big impact: incredibly fine and detailed cutting and cold embossing.

Embossed Braille for folded cartons particularly for the pharmaceutical sector

technical data

| ProCut 76 | |

|---|---|

| PAPER [grams per square meter] | ab 100 g/m² |

| CARDBOARD, MICROWAVE MAX. [grams per square meter] | 1500 g/m² (1.8 mm) |

| PLASTIC (PET, PP, PVC) MAX. [grams per square meter] | 1.500 g/m² |

| MAXIMUM SHEET SIZE [mm, in] | 760 x 600 29.92" x 23.62" |

| MINIMUM SHEET SIZE [mm, in] | 279 x 600 10.98" x 23.62" |

| SPEED [sheets per hour] | 5500 |

| CUTTING FORCE [t, MN] | 165 t (1.65 MN) |

| MAXIMUM CUTTING SIZE [mm, in] | 743 x 585 29.25" x 23.03" |

| GRIPPER MARGIN [mm, in] | 10 .39" |

| DIMENSIONS (lenght x width) [m, ft] | 4.87 x 2.69 15.98' x 8.83' |

* Depending on the material, sheet size and die configuration Technical data and figures are subject to change.

Post-press goes Print 4.0

Digitalising processes, networking machines and establishing integrated workflows.

The central element in the KAMA concept for Print 4.0 is its Cockpit with the Job-Manager software. The Job Manager runs on an industrial PC and centrally manages communications with the KAMA machines, while also serving as an interface for networking and integration in the MIS/ERP system of the customer.

Current jobs are received digitally by the Job-Manager software, providing the operator with all the relevant data on the screen with just a few mouse clicks. The Job-Manager generates matching adjustment data for the machines and transmits them there. This simplifies the process of getting the machine ready for the operator and significantly shortens set-up times.

The machines in turn send their data back to the Job-Manager – including set-up time, duration of production, number of good sheets, rejects and of course information about the current status of production. This data can be forwarded to an MIS/ERP system.

Integration in an MIS/ERP system is prepared on a customer-specific basis. We are currently introducing this for reference customer projects both in commercial printing and in packaging.

Once you have integrated the KAMA machines in your network, all aspects of order management can be handled paperlessly and – what is more important – communication errors can be avoided. The processes are better coordinated with each other, helping to eradicate wasted time, costs and movements (“Muda”). The result: significantly shorter throughput times and faster time-to-market.

Particularly when it comes to short and medium runs, we believe that a networked Print 4.0 approach up to and including the post-press stage is absolutely indispensable.

In a nutshell: KAMA Job-Manager software:

provides networking of KAMA machines for electronic job tickets

digitalises and accelerates set-up processes

determines and communicates adjustment data for the tool-free stripper SBU

determines and transmits adjustment data for optimum foil utilisation during hot foil stamping

acts as a client for networking with the ERP/MIS

Email: Sales@absoluteprintingequipment.com

Phone: (317) 862-9096